SPECIAL HOSES

From our special hose facility in Helsingborg, we deliver, among other things, assembled industrial hoses, construction heating products, welded metal hoses, and transition couplings/adapters.

Since 2022, Dunlop Hiflex has expanded its facilities for assembling industrial hoses by adding a Special Hoses assembly and competency center in Helsingborg, Sweden, to cover the Scandinavian market. This department for special hoses works with quality control, high flexibility, and high availability.

The Special Hoses division is a 2500 m² warehouse and assembly facility for special hoses such as metal hoses, composite hoses, and industrial hoses, with direct delivery across Scandinavia.

The highly skilled technical team from Alfagomma and Dunlop Hiflex is dedicated to performing technical calculations, simulations, and mechanical drawings to help you select the right hoses and fittings and/or develop tailored solutions.

QUALITY SYSTEM

Dunlop Hiflex Special Hoses assembly center works with high quality and reliability. The evaluation of the best solution for your application is based on international standards and regulatory requirements such as (EN 1761, EN 12115, 2004/1935 EC, 2006/2023 EC, 2014/68 EU-PED). The quality system ensures full traceability for all assemblies using laser engraving or other suitable marking methods.

ASSEMBLY METHODS

- Hose crimping from 1/8” to 6”

- Safety clamps (EN14 420 – EN 14 423)

- Hose clamps

- Welding and soldering

TESTS

We provide the following tests and certifications:

- Pressure tests

- Electrical conductivity

- Custom tests upon request

- Certificates of compliance are issued according to EN10204 2.1, 2.2, and 3.1.

EXAMPLES OF SPECIAL HOSES

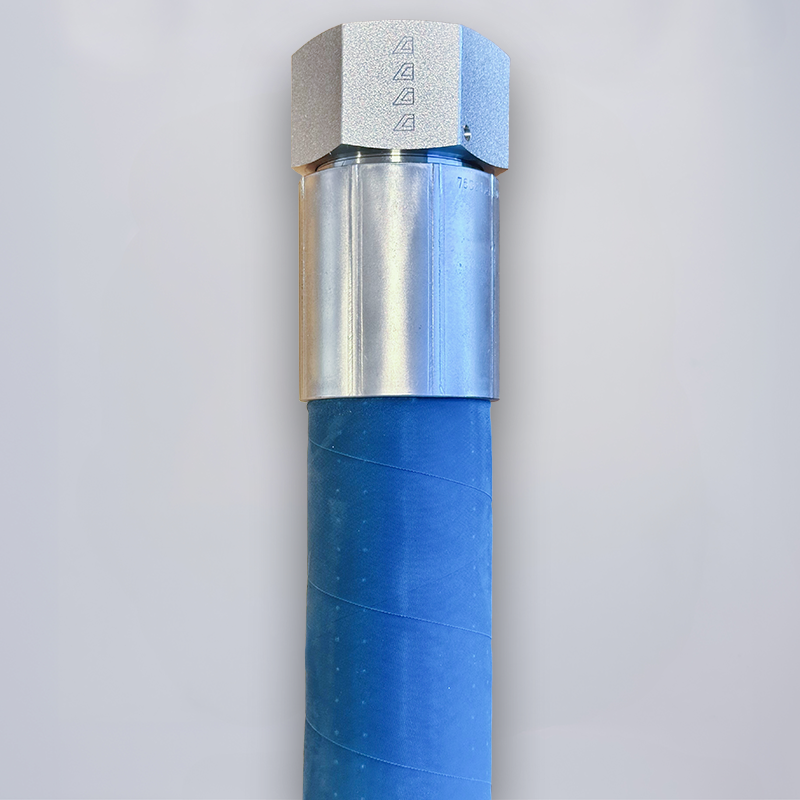

CONCRETE HOSE

Concrete is highly abrasive on hoses and equipment. Therefore, our concrete pump hoses are made with an inner tube of electrically conductive natural rubber with very high abrasion resistance. The outer tube is made from a blend of natural rubber and synthetic rubber for the best weather resistance and durability. The outer tube is also electrically conductive to prevent the buildup of static electricity. The hoses are either steel-reinforced or textile-reinforced depending on the user’s requirements. The couplings, made of hardened steel, are "one piece" and are assembled to ensure full flow through the entire hose. The hoses are approved for a working pressure of 100 bar with steel reinforcement and 85 bar with textile reinforcement.

In addition to rubber hoses, which are available as both coupling hoses (with fittings at both ends) and end hoses (with a fitting on one side), we also offer flat-rolled end hoses in polyurethane in various lengths and dimensions.

The range also includes accessories such as locks, seals, cone pipes, and cleaning balls.

CONSTRUCTION HEATING PRODUCTS

All hoses for construction heating delivered by Dunlop Hiflex are rated for a working pressure of 10 bar. The hoses are made from EPDM with textile reinforcement. The seals in the couplings are also made of EPDM.

The couplings in the construction heating program are manufactured as "one piece" where possible. All joints are assembled with thread locking to ensure the highest safety against leakage and the least possible environmental impact.

METAL HOSE

Metal hoses are used in environments where other hoses do not meet the requirements. For example, in extremely low temperatures (-270 °C) or high temperatures (+550 °C). They can also be used to absorb vibrations or deviations in piping systems.

Dunlop Hiflex supplies corrugated, acid-resistant metal hoses with stainless steel braiding, assembled in our own factory in Helsingborg. All hoses delivered are leak-tested. Pressure testing and other tests, such as X-ray or third-party inspection, can be performed upon request.

ASSEMBLED INDUSTRIAL HOSE

Dunlop Hiflex workshop in Helsingborg can deliver all types of assembled hoses for demanding environments where reliable equipment is crucial. Hoses in all types of rubber, plastic, composite, PTFE, metal, and more.

We work with all types of fittings and couplings in all material grades. We assemble everything from hose clamps and clamp backs to crimp ferrules. With many years of experience from all over the world, most of our industrial hoses have been developed by our own Alfagomma factories to withstand the toughest working conditions.