ABOUT US

Dunlop Hiflex Scandinavia is one of the market's most established suppliers of high-quality hoses and fittings in hydraulics, industry, pneumatics, transmission, industrial rubber, and hydraulic tools.

DUNLOP HIFLEX SCANDINAVIA

Dunlop Hiflex Scandinavia designs, manufactures, and sells high-quality hydraulic hoses, industrial hoses, and couplings. Our hoses can handle almost anything, from the simplest PVC water hose to high-tech rubber hoses intended for the offshore industry. We tailor materials and properties to meet specific requirements. Our hoses are specially developed for demanding applications such as transporting chemicals, oils, concrete, waste, food, and steam, with properties such as flexibility, resistance to high pressure and pressure surges, as well as abrasion resistance.

At Dunlop Hiflex Scandinavia, you always have easy access to expertise, quality, and service. We have good geographic coverage with our own stores and certified distributors throughout Scandinavia, and together with complementary quality products from leading suppliers, we offer our customers a complete solution.

Dunlop Hiflex Scandinavia consists of Sweden, Denmark, and Norway, and we have been established in Sweden since 1969 with our headquarters and central warehouse for the Scandinavian market in Halmstad. We have a large logistics center of 13,000 square meters, and at our production facilities in both Halmstad and Helsingborg, we handle everything from hydraulic hose production, industrial hose production, pipe bending, capping, and assembly according to customer specifications, with deliveries worldwide.

Since 2005, we have been part of the international Italian group Alfagomma Group – one of the leading global manufacturers of hydraulic and industrial hoses.

Magnus Andersson – CEO Dunlop Hiflex Scandinavia

MAGNUS SHARES OUR JOURNEY

In the years since Magnus Andersson took over as CEO of Dunlop Hiflex Scandinavia, we have significantly improved our market position. This has been achieved through a clear strategy, exceptional skill development, and key investments.

In addition to investing in our staff, we are also heavily focused on digitalization in various ways. For example, we have implemented a new Asset Management System that tracks all historical data and allows for the initiation of regular inspections or component replacements at different intervals. We have also essentially rebuilt the entire hose production in Halmstad and invested in three new automatic lift systems, which have contributed to increased picking speed and minimized picking errors.

Innovation and staying at the forefront of our products’ performance and functionality have definitely been strengthened by the acquisition of Dunlop Hiflex by Alfagomma.

"All of this has happened during some rather challenging years – a global pandemic, Russia’s invasion of Ukraine, soaring electricity prices, freight costs, and raw material prices, as well as high inflation and a weak Swedish and Norwegian currency in an uncertain and, to say the least, turbulent business climate. So, it hasn’t been an easy journey – but a fantastic one when we look in the rearview mirror.

I came to a company that was struggling, but today the company’s confidence has been significantly strengthened. It’s amazing to see the results of our hard work on transformation, and I am extremely pleased with where we are today!" – says Magnus.

ALFAGOMMA GROUP

Founded in 1956 by Felice Gennasio, Alfagomma is a global company specializing in the development and manufacture of hydraulic and industrial integrated fluid handling solutions. The Alfagomma Group is headquartered in Milan, Italy with factories and facilities spread over five continents. The group includes brands such as Alfagomma, Dunlop Hiflex, Argus, Sitef and GEFE.Polymers.

As a comprehensive supplier and trusted partner, Alfagomma supports its customers with technical innovation and customized solutions for all applications. This guarantees logistical support for you as a customer regardless of where you are, thanks to the company's global presence with operations in 24 countries. Long experience combined with top modern and patented products guarantee high quality and reliability.

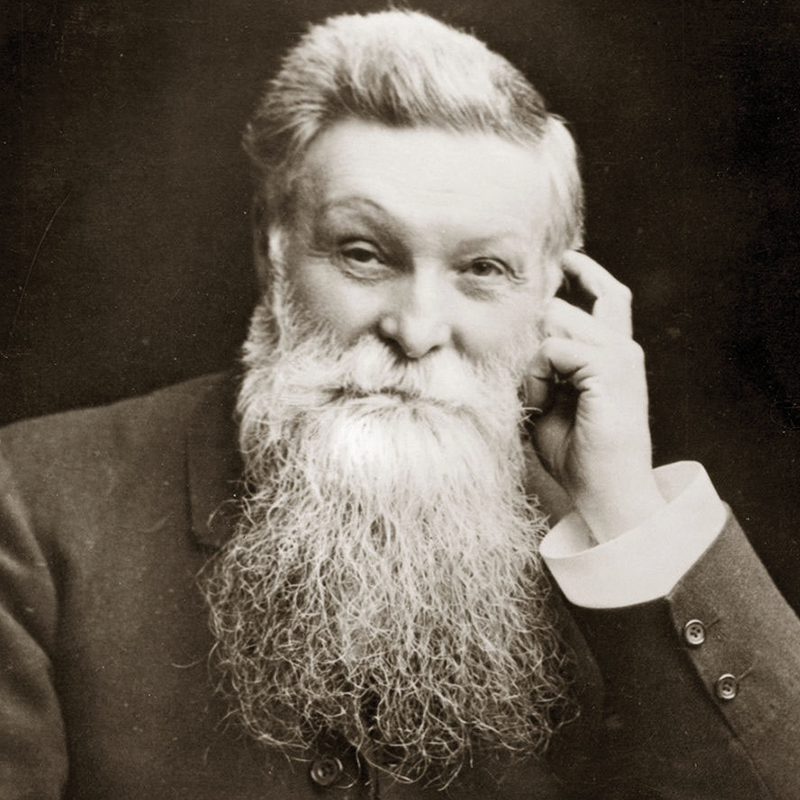

John Boyd Dunlop

OUR HISTORY, OUR HERITAGE AND OUR BRAND

Dunlop Hiflex is part of the Alfagomma Group, where we have many common synergies. We both have a strong innovative streak and ingenuity and a strong brand.

For Dunlop, this began as early as 1887 in Scotland when John Boyd Dunlop watches his son riding a bicycle on a bumpy dirt road. The bike has massive tires and the ride is hard and bumpy. John then comes up with the idea of wrapping an air-filled rubber tube around the rim and thus history is made.

Since 1969, Dunlop Hiflex has been in Sweden with headquarters in Halmstad, a lot has happened since the beginning and we proudly carry the brand, the heritage and our history, which originated from a Scotch and an air-filled rubber tube on a bicycle.

1887Air-filled rubber tires are detected

John Boyd Dunlop invents the air-filled rubber tire1898Gummi K Lund is founded in Norway

1899Dunlop Rubber Company is founded in England

1912 British Tire & Rubber (BTR) is founded in England

1914BTR A/S is founded in Denmark

1956Alfagomma is founded

Felice Gennasio founds Alfagomma1969BTR AB is founded in Sweden

1985BTR plc acquires the Dunlop Group

The entire Dunlop group is acquired by BTR plc, but the tire division was immediately sold on1995GKL is acquired

GKL is acquired and integrated into the BTR group2003Hiflex Sweden AB changes its name

Hiflex Sweden AB changes its name to Dunlop Hiflex AB2005Alfagomma SpA acquires the entire Dunlop Hiflex group

2008Dunlop Hiflex AB becomes the HQ for Scandinavia

A new central warehouse of a total of 13 000 square meters is being built2023The Special Hose Division opens in Sweden

Special Hose Division opens in Helsingborg, Sweden

OUR OPERATIONS

Dunlop Hiflex Scandinavia has its headquarters in Halmstad and a strong local presence in the other Scandinavian countries. We have an efficient production and warehouse operation in Halmstad that serves as the central warehouse for all Scandinavian countries. To meet our customers' needs for proximity and service, we are also present in a number of locations in Scandinavia with local production, hose service and store sales.

We are specialists in flow management and hydraulics, for both low, medium and high pressure applications.

We are proud of our high-quality products that we ourselves developed, tested, manufactured and ensured that all components are of the highest class and are tested together to ensure pressure measurements, safety, quality and exceed the requirements and regulations that exist.

We can offer everything from individual components and spare parts to complete kits and system solutions including pipe bending, end forming, welding, hose assembly, hybrid solutions, block assembly and design as well as construction of hydraulic units, depending on the customer's wishes regarding packing, marking, testing, test pressure, flushing and logistics.

Our vision – Preferred partner in the Scandinavian Hydraulic & Fluid Conveyance market.

DRIVES DEVELOPMENT FORWARD

DEVELOPMENT

Alfagomma has a long experience and strategy around innovation and development of products with the goal of being the leading player in the product area of management components and complete system solutions. An important part of supporting this active initiative is to both recruit competence and invest in production efficiency and digitization.

RESEARCH & DEVELOPMENT

We work with continuous improvements. In our advanced and ultra-modern development center in Teramo, our technical team works to develop and create the products of the future.

Our goal is to always exceed international standards to improve product performance, safety and longevity.

INTELLECTUAL INNOVATION

The success of our Team in research and development and the company's global position can be measured by the number of registered and approved patents.

Today, Alfagomma Group has 72 different registered unique patents.

OUR BUSINESS SEGMENTS

An important part of our product development and digitization is that, with the help of this software, we can simulate the products during product development before they go into series production in order to achieve the best possible performance for our customers' various applications.

SEGMENT MOBILE OEM

As a global partner to customers with serial production of machines or vehicles, Dunlop Hiflex works in all stages of the manufacturing process. From an early development stage with design and construction, via prototype and application review to customized logistics.

SEGMENT STATIONARY OEM

As a global supplier to customers with tough requirements in industry such as the mining industry, steel mills, paper pulp, wind power, off-shore, the fishing industry and other customer categories that place high demands on performance, cleanliness and safety, we have developed special unique products that fit those particular applications.

SEGMENT AFTERMARKET

We reach our end customers through our own stores, as well as through our certified dealers. We can deliver your order directly to you at the specified location. You also have the choice to order in advance and collect from us. We also offer more services to adapt to our customers' needs.